Transforming Energy for America

Coil Sizing

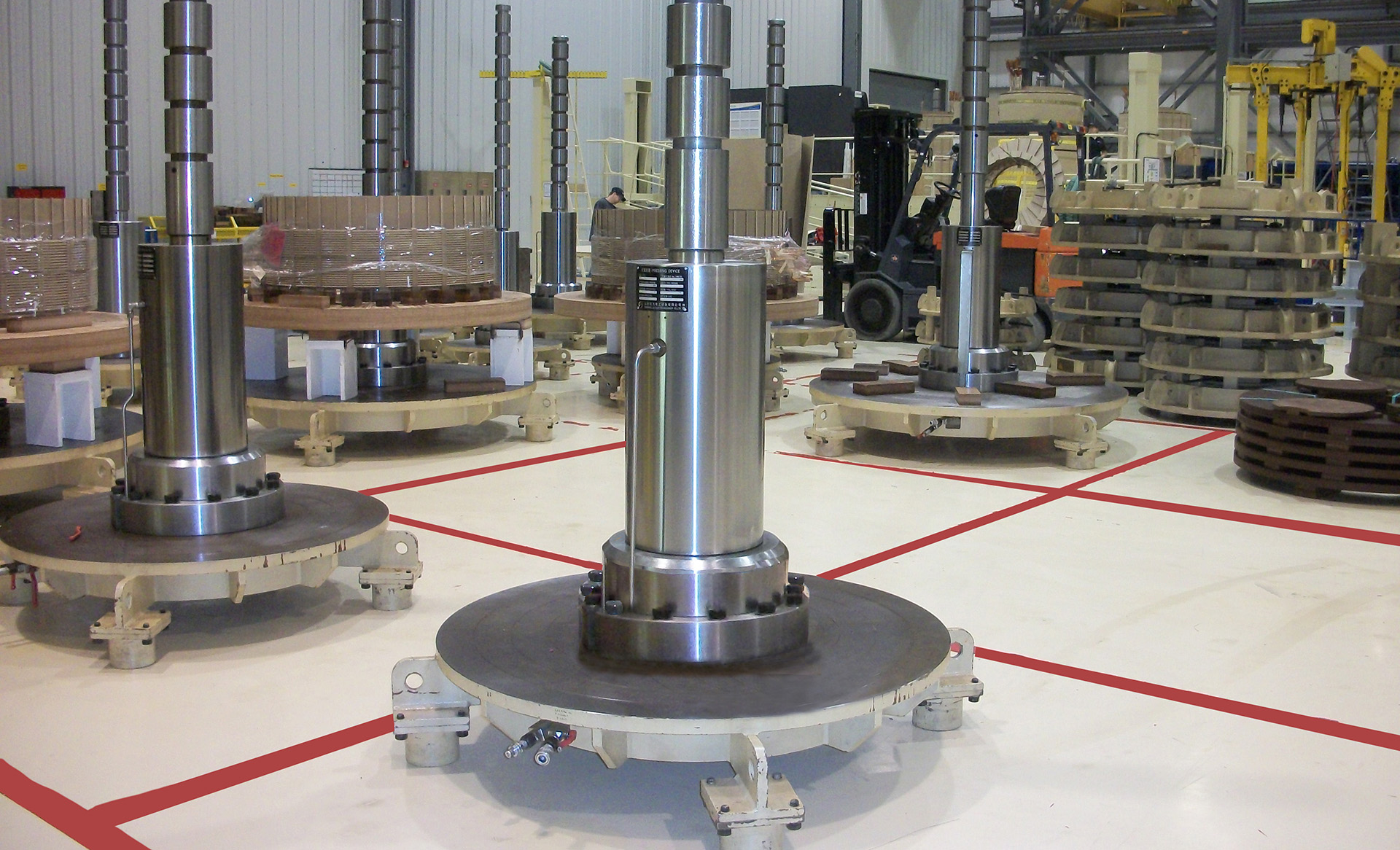

Coils need careful handling through the drying, pressing, and sizing operations. All coils are dried then oil-sprayed using a vapor-phase drying (VPD) process under isostatic pressure. Isostatic compression stabilizes the actual height during the drying process. Windings are kept compressed until nesting to avoid axial spring-back.

To make sure this process is flawless, we use a home-grown, high-tech device we call a “winding mushroom.” The mushroom ensures that isostatic compression is uniform and continuous throughout the VPD process. This process is crucial in meeting the design parameters for short circuit.